How Do You Correctly Set Up a Danfoss FC102 Drive for HVAC Systems?

Modern HVAC systems rely heavily on precise control and energy-efficient operation, and variable speed drives (VSDs) play a crucial role in delivering that performance. Setting up an HVAC drive correctly is not just about getting it to work—it’s about ensuring optimal efficiency, long-term reliability, and compliance with building regulations. One of the most popular drives in the UK market for HVAC applications is the Danfoss FC102, known for its flexibility and energy-saving features. In this blog, we walk you through how to correctly set up a variable speed drive like the Danfoss FC102, with tips that apply broadly to similar VSDs and Danfoss inverters.

What Are the Initial Checks Before Setup?

Before starting the configuration of any drive, it’s essential to carry out some initial site and equipment checks. These help prevent costly mistakes and ensure a smooth setup. First, inspect the drive physically for any signs of damage, especially if it’s just been delivered. Confirm that the drive model, power rating, and voltage class match the requirements of your HVAC system. For example, the Danfoss FC102 is available in multiple power sizes, so it’s vital to select the one that aligns with the motor’s specifications.

Ensure the drive is mounted in an appropriate enclosure, especially in HVAC plant rooms that may be humid or dusty. If the environment is harsh, an IP66-rated drive like this one may be necessary. Adequate spacing and cooling around the drive must also be observed as per the manufacturer’s guidelines.

How Should the Electrical Wiring Be Done?

Proper electrical installation is critical. Start by disconnecting the mains supply to avoid any electrical hazards. Then, connect the incoming power supply to the correct terminals, typically marked L1, L2, and L3 for three-phase drives. The motor connections should go to U, V, and W terminals. It’s recommended to use shielded cables for both input and output connections to minimise electromagnetic interference, particularly important in HVAC systems within commercial buildings. Don’t forget to connect the earth cables properly. The drive’s grounding must be sound to protect against surges and ensure safety compliance.

What Parameters Should Be Set First?

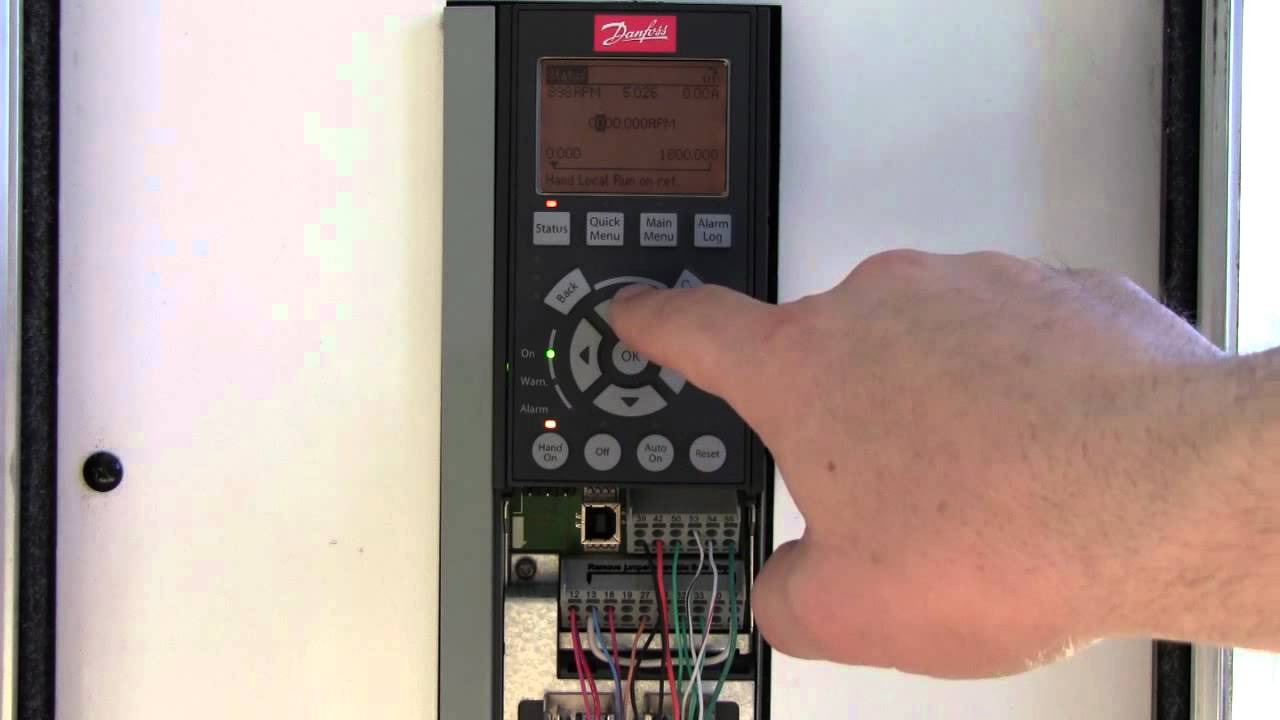

Once the drive is powered up, begin by performing a factory reset to ensure no residual settings from previous configurations interfere with your setup. Most drives have a quick setup menu or wizard—make use of this to configure the basic parameters.

Key parameters to start with include:

- Motor voltage, current, and frequency: These should match the motor’s nameplate.

- Motor control type: Choose between V/f (volts per hertz) or sensorless vector control, depending on your HVAC application.

- Ramp-up and ramp-down times: These affect how quickly the motor reaches operating speed or stops.

- Minimum and maximum frequency: This defines the operational limits of your fan or pump.

With the Danfoss inverter series, including the FC102, these values can be easily adjusted via the local control panel or software interface.

How Do You Configure Inputs and Outputs?

Digital and analogue inputs and outputs are crucial for communicating with external control systems like BMS (Building Management Systems). Set up the digital inputs for commands such as start/stop or direction change. For HVAC applications, an analogue input is often used for speed reference, commonly from a 0-10V or 4-20mA signal generated by a thermostat or pressure sensor. The analogue output can be configured to relay feedback such as output frequency or motor current, allowing your BMS to monitor the drive’s performance in real-time. Ensure that all I/O connections are properly mapped in the drive’s software and tested for accuracy.

What About PID Control in HVAC Systems?

In many HVAC systems—especially those involving temperature or pressure regulation—PID (Proportional-Integral-Derivative) control is crucial. It enables the drive to automatically adjust motor speed based on a setpoint, like room temperature or duct pressure. To set up PID:

- Input your setpoint source (either fixed or from an analogue input).

- Set the feedback signal source (typically from a sensor).

- Tune your P, I, and D values. Start with manufacturer defaults and adjust gradually for optimal response without oscillations or delays.

The Danfoss FC102 has a built-in PID controller, making it especially suited for applications such as variable air volume (VAV) systems or chilled water pumps.

How Do You Test and Commission the Drive?

Before commissioning, double-check all electrical connections and parameter settings. Run the motor in manual mode first to observe basic operation. Gradually increase the speed to ensure smooth acceleration and deceleration. Then, switch to automatic mode using your control input, such as a BMS signal. Observe the drive’s response to changes in setpoint or load. Check key indicators on the display—frequency, current, temperature, and fault codes.

Document all settings, especially if the system will be handed over to a facilities management team. Label wiring and maintain a record of all parameter changes for future servicing.

What Faults Should You Look Out For?

Even with a successful setup, issues can arise. Common faults include:

- Overcurrent or overload faults: Usually caused by incorrect motor data or a jammed load.

- Undervoltage: Can indicate a weak supply or loose wiring.

- Overtemperature: Ensure the drive has proper ventilation and isn’t running beyond its rated capacity.

Most drives provide diagnostic tools and fault logs, making troubleshooting straightforward. The Danfoss inverter platform also supports remote monitoring and diagnostics, which can be a huge benefit for larger sites.

How Can You Optimise the Drive for Energy Efficiency?

Finally, after the drive is operational, consider fine-tuning it for energy savings. Many HVAC drives, including the Danfoss FC102, offer energy optimisation modes. These can reduce motor energy consumption during partial load conditions.

You can also schedule drive operation via built-in timers or external controllers, limiting run time to when needed. Monitor energy usage regularly using the drive’s built-in energy meter and adjust your strategy accordingly.

Final Thoughts

Setting up a variable speed drive like the Danfoss FC102 correctly is essential for a reliable and efficient HVAC system. While the process may seem technical, following a structured approach—from installation to commissioning and optimisation—ensures the drive works in harmony with your broader building systems. For engineers and facilities managers in the UK, investing the time to configure the drive properly pays off in energy savings, reduced downtime, and easier long-term maintenance.